The long-standing research question of the plastic deformation of materials and components is intrinsically related to the propagation of slip across interfaces such as grain boundaries or phase boundaries. Despite intense work, current approaches do not provide a comprehensive overview of plasticity propagation, and mechanisms of slip transfer remain to date fundamentally unclear. We explored this question by investigating elementary mechanisms of slip transfer through grain-boundaries and phase-boundaries, by means of atomistic simulations based on semi-empirical potentials.

Slip transfer at grain-boundaries in aluminum

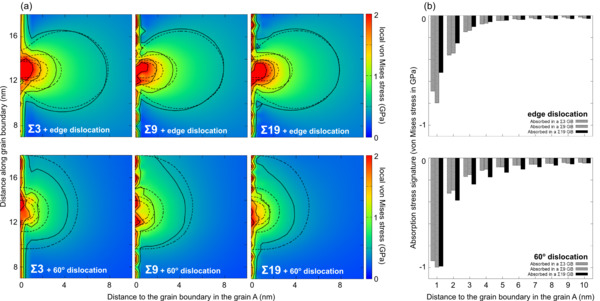

In order to anderstand the very basic physical origin of slip transfer at grain-boundaries (GB), we study the absorption of dislocations at high-angle GB. For example, we characterize the residual stress field after absorption.

Fig. 1: (a) local von Mises stress distribution σvm obtained from the atomic stress and averaged over the whole dislocation line length, for an absorbed edge and 60o dislocation in the specified GB (solid iso-lines and color scale). The iso-lines are plotted every 500 MPa. The dashed iso-lines represent the corresponding dislocation in bulk. (b) absorption stress signature of an absorbed edge and 60o dislocation in GBs. [unpublished work]

Fig. 1: (a) local von Mises stress distribution σvm obtained from the atomic stress and averaged over the whole dislocation line length, for an absorbed edge and 60o dislocation in the specified GB (solid iso-lines and color scale). The iso-lines are plotted every 500 MPa. The dashed iso-lines represent the corresponding dislocation in bulk. (b) absorption stress signature of an absorbed edge and 60o dislocation in GBs. [unpublished work]

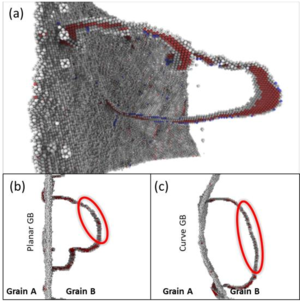

Elementary mechanisms for the slip transfer at GB are often studied with well defined planar GB. Here, we perform controlled studies of slip transfer at curved grain-boundaries in aluminum bi-crystals. In particular, we highlight the importance of the curvature in favoring dislocation transmission.

Fig. 2: Slip transfer at a curve grain boundary in aluminum. (a) perspective view of a transferred dislocation. Top views of the slip transferred across (b) planar and (c) curve grain boundary. [unpublished work]

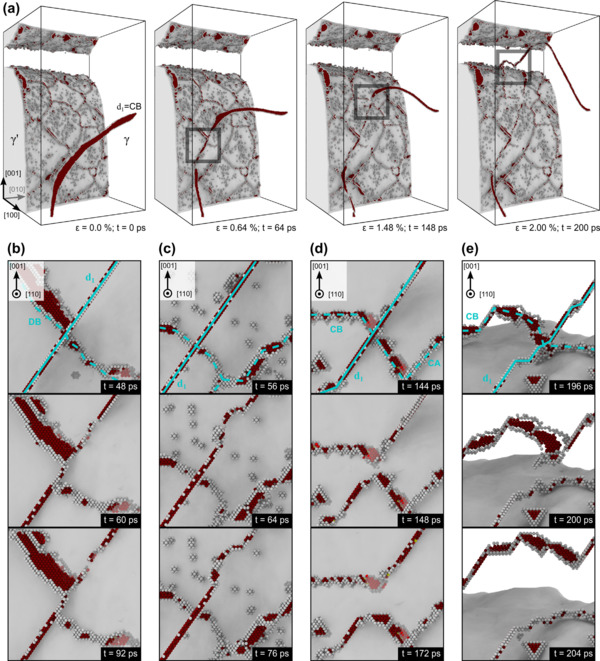

Slip transfer at phase-boundaries in Nickel based superalloys

The interaction of dislocations with precipitates is an essential strengthening mechanism in metals, as exemplified by the superior high-temperature strength of Ni-base superalloys. Here we use atomistic simulation samples generated from atom probe tomography data of a single crystal superalloy to study the interactions of matrix dislocations with a gamma-prime precipitate in molecular dynamics simulations. It is shown that the precipitate morphology, in particular its local curvature, and the local chemical composition significantly alter both, the misfit dislocation network which forms at the precipitate interface, and the core structure of the misfit dislocations. Simulated tensile tests reveal the atomic scale details of many experimentally observed dislocation–precipitate interaction mechanisms, which cannot be reproduced by idealized simulation setups with planar interfaces. We thus demonstrate the need to include interface curvature in the study of semicoherent precipitates and introduce as an enabling method atom probe tomography-informed atomistic simulations.

Fig. 3: Interaction of one 60° matrix dislocation with the misfit dislocation network in the APT-informed sample. (a) Deposition of dislocation segments at the interface during tensile loading. (b)–(d) Details of specific dislocation processes which are highlighted by gray rectangles in (a). (b) Intersection of an orthogonal misfit dislocation by the deposited dislocation. (c) Local climb of the dislocation by absorption of vacancies at the interface. (d) collinear reaction with a misfit dislocation of identical Burgers vector leaving a gap along the line of the deposited dislocation. (e) Knitting-out of a misfit dislocation by a dislocation. [From Prakash, Guénolé et al., Acta Mater. 92 (2015) 33-45]